Y.V. Phani Kumari, from

the institute of Telangana. and Kavita Waghray, from the institute of

Telangana. wrote a Research Article about, Probiotic Bacteria from Neera:

Extending Fresh Produce Shelf Life. Entitled, Isolation and Identification of

probiotic bacteria from natural Neera to extend the shelf life of fresh fruits

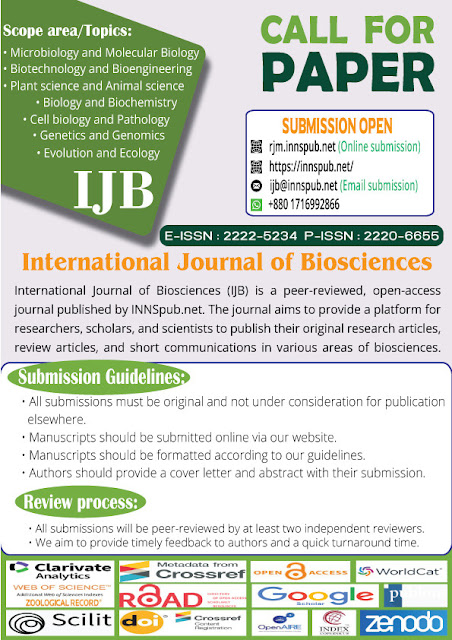

and vegetables. This research paper published by the International Journal of Biosciences (IJB). an open access scholarly research journal on Biosciences.

under the affiliation of the International Network For Natural Sciences |

INNSpub. an open access multidisciplinary research journal publisher.

Abstract

Packaging and processing techniques in the food sector can adversely impact both consumer health and the environment. Consequently, there’s a growing demand for minimally processed foods that retain their nutritional and sensory qualities while ensuring extended shelf life. Edible coatings have emerged as a promising solution, offering improved quality, safety, and functionality for perishable items like fruits and vegetables. These coatings regulate water diffusion, gas permeability, and oxidation, and can be applied through dipping, spraying, or coating methods. A recent study focused on isolating probiotic bacteria from Neera samples collected near Choutuppal in Nalgonda, Telangana. Ten bacterial strains were cultivated from these samples on MRS agar and subsequently sub-cultured to obtain pure cultures. Morphological analysis confirmed the purity of each culture. The isolates were then assessed for antimicrobial activity against spoilage-causing microorganisms in fruits and vegetables. Biochemical tests, including catalase, methyl red, oxidase, starch hydrolysis, citrate utilization, and Voges-Proskauer tests, were conducted to characterize the isolates. Among the ten strains, isolate 3 demonstrated the most promising characteristics, including strong antibacterial activity. Molecular identification using universal 16S rRNA primers identified this isolate as Levilactobacillus brevis. Phylogenetic analysis using Mega-4 bioinformatics software further confirmed its identity. This strain exhibited excellent performance in bile salt tolerance tests and demonstrated other probiotic activities, highlighting its potential as a functional food ingredient. The findings underscore the significance of probiotics in enhancing food quality and safety, offering a natural solution to meet consumer preferences for healthier and longer-lasting food options.

Introduction

Fruits and vegetables are an important part of a healthy diet due to their low-calorie content (Charlton et al., 2014) and several health benefits (Berger et al., 2010). Consuming a diet rich in fruits and vegetables has been shown to lower the risk of several diseases, including cardiovascular disease, colon cancer, obesity, and diabetes (More et al., 2020). They have become increasingly popular in recent years, and their richness of nutrients makes them necessary for everyday use (Leneveu-Jenvrin et al., 2020). Producing minimally processed fruits and vegetables has helped meet the rising demand for fresh produce (both whole and cut) in many developed countries over the past decade. This is because these foods are both nutritious and easy to prepare. Fruits and vegetables that can be stored for longer without losing their quality are one way in which minimal processing techniques are replacing more conventional ones (De Corato et al., 2020; Hasan et al., 2020). Food quality declines during preservation, a major issue for food manufacturers and a significant contributor to food waste. Recently, novel and effective food handling methods have been invented to lead to the extension of food safeguarding, shelf-life extension, and, thus, food waste decrease (Stan et al., 2019; Stan, 2020; Verma et al., 2021; Chitrakar et al., 2021; Nezami, 2020). But not all of these cutting-edge technologies are viable commercial solutions because they influence customer behavior (Rabadán et al., 2021; Stefanoiu et al., 2018). Edible packaging, coatings, and films are novel solutions to this issue because they protect perishable goods, delaying spoilage from microorganisms and preventing loss of moisture and gas (Dehghani et al., 2018).

Research into edible packaging systems is increasing annually as more people seek less conventional and more nutritious foods. Senses of smell, taste, and sight can be preserved using edible films and coatings as the principal packaging material for goods with edible ingredients. The ripening of produce coated with edible films is slowed, and its shelf life is extended (Hassan et al., 2018; Ulusoy et al., 2018). Wax was applied to oranges in China in the 12th and 13th centuries to create an edible coating. Edible coatings produced from boiling soybeans were developed in Japan in the 15th century (Tural et al., 2017) and were used to enhance the visual appeal of various foods. The edible packaging industry has proliferated in the past few years, with a projected valuation of $1097 million by 2023 (Mamtani et al., 2021). Edible packaging has two separate applications in the food sector. Edible coatings can be sprayed directly onto the food item or onto a prefabricated film that is then coiled around the food item (Suhag et al., 2020).

The food sector needs help with customer acceptability regarding novel manufacturing methods, such as edible coatings and films (Vital et al., 2018), even though these can assist in extending the shelf life of numerous food items. Consumer acceptability is vital to the production of effective food products. Hence insight into how consumers create and interpret opinions about novel technology and goods is essential for food chain invention (Stan et al., 2019; Siegrist et al., 2021). Several studies have been conducted to determine whether or not consumers will embrace novel processing technologies and techniques, such as nanotechnology (Peters et al., 2016), radio frequency (Stefanoiu et al., 2018), food irradiation (MacRitchie et al., 2014), and edible coatings and films (Wan et al., 2007). This investigation examines the current state of knowledge regarding the use of edible formulations on a variety of less processed fruits and vegetables, with a particular emphasis on the scientific aspects of this practice, involving coating ingredients and composition, implementation techniques, and the impact on food shelf life and quality, which involves nutritional quality.

Probiotics are live bacteria that

help humans stay healthy. Maintaining viability and metabolic activity is

essential from when food is harvested until the consumer consumes it. Although

protecting against these microbes is crucial, the question of when and where to

release them still needs to be answered. There is no issue with release when

employing edible

Using these beneficial microbes has been reported to decrease oxidative stresses and inflammatory mediators (Mohammadi et al., 2015; Mohammadi et al., 2015), as well as remove poisons and heavy metals (Massoud et al., 2020; Siahmoshteh et al., 2016). As stated by Hosseini et al. (2013) and Soheili et al. (2011), prebiotics are used to promote the development of probiotics. More research into the human gut microbiome can lead to identifying hitherto unrecognized prebiotics and probiotics (Gómez et al., 2016). Probiotics' survival and metabolic activity must be preserved through food manufacturing, after ingestion, and within the gastrointestinal system (Nguyen et al., 2016). For example, lactic acid bacteria have been shown to increase the nutritional value of foods by contending with pathogens for nutrients (such as vitamins, minerals, trace elements, and peptides) and by creating organic acids and bacteriophages (antimicrobial peptides) to combat spoilage during storage. Thus, using probiotics might lengthen the period that vegetables and fruits can be stored, avoiding being linked to their antagonistic effects (Alegre et al., 2011). Protecting fruits and vegetables with edible coverings has become a common practice recently. By limiting postharvest moisture loss, gas exchange, respiration, and oxidative processes, edible coating with semipermeable films might extend the storage life of fruit (Khodaei et al., 2019; Petriccione et al., 2015). Films and coatings for edibles can be fabricated from a wide range of biocompatible materials, including lipids, polysaccharides, proteins, and their respective combinations (Pereira et al., 2016). The food packaging business and the network of edible polymer films can both benefit from the incorporation of probiotics. An alternate strategy for managing dangerous microbes and bolstering food safety is provided by incorporating probiotics and other active chemicals into the structure of biopolymers. Research on both probiotics and food packaging has increased over the past two decades (Espitia et al., 2016), yet there has been relatively little research on the use of probiotics in food packaging. It was first suggested in 2007 (Tapia et al., 2007) that probiotics may be used in consumable films. Therefore, there is continuing investment in the study and production of probiotics films and coatings for proactive packaging. These coatings and films could serve as viable replacements for transporting probiotics. Active or bioactive packing, like probiotic material for packaging, can improve food stability and even positively affect the health of the customer. This research aimed to determine which strains of lactic acid bacteria could be isolated from Neera to improve food safety and shelf life without sacrificing nutritional value.

Reference

Alegre I, Viñas I,

Usall J, Anguera M, Abadias M. 2011. Microbiological and physicochemical

quality of fresh-cut apple enriched with the probiotic strain Lactobacillus

rhamnosus GG. Food Microbiol 28(1), 59–66.

Beheshtipour H,

Mortazavian AM, Haratian P, Khosravi-Darani K. 2012. Effects of Chlorella

vulgaris and Arthrospira platensis addition on viability of probiotic bacteria

in yogurt and its biochemical properties. Eur Food Res Technol 235, 719–728.

Beheshtipour H,

Mortazavian AM, Mohammadi R, Sohrabvandi S, Khosravi Darani K. 2013

Supplementation of spirulina platensis and chlorella vulgaris algae into

probiotic fermented milks Comprehensive Reviews in Food Science and Food

Safety 12, 144–154.

Berger CN, Sodha SV,

Shaw RK, Grin PM, Pink D, Hand P, Frankel G. 2010. Fresh fruit and

vegetables as vehicles for the transmission of human pathogens. Environmental

Microbiology 12, 2385–2397.

Charlton K, Kowal P,

Soriano MM, Williams S, Banks E, Vo K, Byles J. 2014. Fruit and vegetable

intake and body mass index in a large sample of middle-aged Australian men and

women. Nutrients 6, 2305–2319.

Chitrakar B, Zhang M,

Bhandari B. 2021. Improvement strategies of food supply chain through

novel food processing technologies during COVID-19 pandemic. Food

Control, 125, 108010.

Dadgar M,

Khosravi-Darani K, Tofighi A, Khanbeigi-Dogahe A. 2014. Effect of

Storage in the fortified probiotic corn flakes preparedby L. plantarum and L.

reuteri. NFSR 1(1), 9–16.

De Corato U. 2020.

Improving the shelf life and quality of fresh and minimally processed fruits

and vegetables for a modern food industry: A comprehensive critical review from

the traditional technologies into the most promising advancements. Critical

Reviews in Food Science and Nutrition 6, 940–975.

Dehghani S, Hosseini

SV, Regenstein JM. 2018. Edible films and coatings in seafood

preservation: A review. Food chemistry 240, 505–513.

Deliza R, Rosenthal A,

Silva ALS. 2003. Consumer attitude towards information on non-conventional

technology. Trends in Food Science and Technology 14, 43–49.

E Silva JPS, Freitas

AC. 2014. Probiotic bacteria: fundamentals, therapy, and technological

aspects. Crc Press. New York, 23–120 p.

Espitia PJ, Batista RA,

Azeredo HM, Otoni CG. 2016. Probiotics and their potential applications in

active edible films and coatings. Food Research International 90, 42–52.

Farhadi S, Khosravi

Darani K, Mashayekh M, Mortazavian AM Mohammadi A, Shahraz F. 2013.

Production of propionic acid in a fermented dairy beverage. Int J Dairy Technol 66, 127–134.

International Journal of Dairy Technology.

Gholami Z,

KhosraviDarani K. 2014. An overview of conjugated linoleic acid: microbial

production and application. Mini-Reviews in Medicinal Chemistry 14, 734–774.

Gómez C, Salminen S. 2016.

Novel probiotics and prebiotics: how can they help in human gut microbiota

dysbiosis. Applied Food Biotechnology 3(2), 72–81.

Hasan SMK, Ferrentino

G, Scampicchio M. 2020. Nanoemulsion as advanced edible coatings to

preserve the quality of fresh-cut fruits and vegetables: A review.

International Journal of Food Science & Technology 55, 1–10.

Hassan B, Chatha SAS,

Hussain AI, Zia KM, Akhtar N. 2018. Recent advances on polysaccharides,

lipids and protein based edible films and coatings-a review. International Journal

of Biological Macromolecules 109, 1095–1107.

Hosseini SM,

Shahbazizadeh S, Khosravi Darani K, Mozafari MR. 2013. Spirulina

paltensis: food and function. Current Nutrition & Food Science 9, 189–193.

Javanmard A, Rahmati

Roudsari M, Mortazavian AM, Sohrabvandi S, Khosravi-Darani K. 2013. The

impact of inoculation rate and order on physicochemical, microstructural and

sensory attributes of probiotic Doogh. Iranian Journal of Pharmaceutical

Sciences 12(4), 917-924.

Khanbagi Dogahe M,

Khosravi-Darani K, Tofighi A, Dadgar M, Mortazavian AM. 2015. Effect of

process variables on survival of bacteria in probiotics enriched pomegranate

juice. British Biotechnology Journal 5(1), 37–50.

Khodaei D,

Hamidi-Esfahani Z. 2019. Influence of bioactive edible coatings loaded

with Lactobacillus plantarum on physicochemical properties of fresh

strawberries. Postharvest Biology and Technology 156, 110944.

Leneveu-Jenvrin Q,

Quentin B, Assemat S, Hoarau M, Meile JC, Remize F. 2020. Changes of

quality of minimally-processed pineapple (Ananas comosus, var. ‘Queen

Victoria’) during cold storage: Fungi in the leading role. Microorganisms 8, 185.

MacRitchie LA, Hunter

CJ, Strachan NJC. 2014. Consumer acceptability of interventions to reduce

Campylobacter in the poultry food chain. Food Control 35, 260–266.

Malganji S, Sohrabvandi

S, Jahadi M, Nematollahi A, Sarmadi B. 2016. Effect of refrigerated

storage on sensory properties and viability of probiotic in grape drink. Appl

Food Biotechnol 3(1), 59–62.

Mamtani K. 2017–2023.

Edible Packaging Market by Material (Lipids, Polysaccharides, Proteins,

Surfactants, and Composite Films), and End Users (Food & Beverages and

Pharmaceuticals)-Global Opportunity Analysis and Industry Forecast,. Available

online: https://www.alliedmarketresearch.com/edible-packaging-market.

Massoud R,

Fadaei-Noghani V, Khosravi-Darani K. 2015. The effect of homogenization

pressure and stages on viability of probiotic bacteria and overall

acceptability of low-fat probiotic yoghurt. EJFPP 6(1), 37–52.

Massoud R,

Khosravi-Darani K. 2015. Biopeptides in milk: opiate and antithrombotic

effects. Mini-Reviews in Medicinal Chemistry 15, 872–87.

Massoud R,

Khosravi-Darani K, Sharifan A, Asadi GH, Younesi H. 2020. The biosorption

capacity of Saccharomyces Cerevisiae for cadmium in milk. Dairy 1(2), 169–176.

Mohammadi AA, Jazayeri

S, Khosravi-Darani K, Solati Z, Mohammadpour N, Asemi Z, Adab Z, Djalali M, Tehrani-Doost

M, Hosseini M, Eghtesadi S. 2015. The effects of probiotics on mental

health and hypothalamic-pituitary-adrenal axis: a randomized, double -blind,

placebo-controlled trial in petrochemical workers. Nutritional

Neuroscience 19(9), 387–395.

Mohammadi AA, Jazayeri

S, KhosraviDarani K, Solati Z, Mohammadpour N, Asemi Z, Adab Z, Djalali M,

Hosseini M, Eghtesadi S. 2015. Effects of probiotics on biomarkers of

oxidative stress and inflammatory factors in petrochemical workers: a

randomized, double blind, placebo controlled trial. International Journal of

Preventive Medicine 6, 82.

More AS, Ranadheera CS,

Fang Z, Warner R, Ajlouni S. 2020. Biomarkers associated with quality and

safety of fresh-cut produce. Food Bioscience 34, 100524.

Nair MS, Tomar M, Punia

S, Kukula-Koch W, Kumar M. 2020. Enhancing the functionality of

chitosan- and alginate-based active edible coatings/films for the preservation

of fruits and vegetables: A review. International Journal of Biological

Macromolecules 164, 304–320.

Nezami MA, Ehsani MR,

Sani AM, Khosravi-Darani K. 2014. Optimization of Lactobacillus

acidophilus La-5, feta cheese starters and salt content in Iranian

ultrafiltered soft cheese formula. Annu res rev 4(24), 4091-4103.

Nguyen HT, Truong DH,

Kouhoundé S, Ly S, Razafindralambo H, Delvigne F. 2016. Biochemical

engineering approaches for increasing viability and functionality of probiotic

bacteria. International Journal of Molecular Sciences 17(6), 867.

Pereira JO, Soares J,

Sousa S, Madureira AR, Gomes A, Pintado M. 2016. Edible films as carrier

for lactic acid bacteria. LWT-Food Science and Technology 73, 543–550.

Peters RJB, Bouwmeester

H, Gottardo S, Amenta V, Arena M, Brandhoff P, Marvin HJP, Mech A, Moniz

FB, Pesudo LQ. 2016. Nanomaterials for products and application in

agriculture, feed and food. Trends in Food Science and Technology 54,155–164.

Petriccione M, De

Sanctis F, Pasquariello MS, Mastrobuoni F, Rega P, Scortichini M, Mencarelli F. 2015.

The effect of chitosan coating on the quality and nutraceutical traits of sweet

cherry during postharvest life. Food Bioprocess Technol 8(2), 394–408.

Rabadán A. 2021.

Consumer Attitudes towards Technological Innovation in a Traditional Food

Product: The Case of Wine. Foods 10, 1363.

Siahmoshteh F,

Hamidi-Esfahani Z, Razzaghi-Abyaneh M. 2016. Antifungal activity,

biodegradation and production inhibition of aflatoxins B. Journal of Pure

and Applied Microbiology 10, 2541–2549.

Soheili M,

Khosravi-Darani K. 2011. The potential health benefits of algae and micro

algae in medicine: a review on Spirulina platensis. Current Nutrition &

Food Science 7(4), 279–285.

Stan A, Bujor OC, Haida

G, Badulescu L, Asanica A. 2019. Monitoring the quality parameters for

organic raspberries in order to determine the optimal storage method by

packaging. Acta Horticulturae 1277, 461–468.

Stan A, Butac M, Ion

VA, Cătuneanu I, Frîncu M, Bădulescu L. 2020. Post-harvest technologies influences

in organic ‘Tita’ plums quality. Scientific Papers: Series B.

Horticulture., LXIV, 105–112.

Stefanoiu GA, Popa EE,

Mitelut AC, Popa ME. 2018. Marketing research regarding consumer

perceptions on using radio frequency in bakery production. Scientific Bulletin

Biotechnology, XXII, 119–124.

Suhag R, Kumar N,

Petkoska AT, Upadhyay A. 2020. Film formation and deposition methods

of edible coating on food products: A review. Food Research International 136,

109582.

Tapia M, Rojas-Graü M,

Rodríguez F, Ramírez J, Carmona A, Martin-Belloso O. 2007.

Alginate-and gellan-based edible films for probiotic coatings on fresh-cut

fruits. Journal of Food Science 72(4), E190–E196.

Tavakoli M,

Hamidi-Esfahani Z, Hejazi MA, Azizi MH, Abbasi S. 2016. Probiotic

potential of Lactobacillus strains isolated from Mazandaran local cheese.

Iranian Journal of Nutrition Sciences and Food Technology 11, 89–98.

Tural S, Sarıcaoğlu FT,

Turhan S. 2017. Edible film and coatings: Production, application methods,

functions and uses in muscular foods. Acad. Food, 15, 84–94.

Ulusoy BH, Yildirim FK,

Hecer C. 2018. Edible films and coatings: A good idea from past to

future technology. Journal of food technology research 5, 28–33.

Verma T, Byron D,

Chaves BD, Irmak S, Subbiah J. 2021.Pasteurization of dried basil leaves

using radio frequency heating: A microbial challenge study and quality

analysis. Food Control 124, 107932.

Vital ACP, Guerrero A,

Kempinski EMB, de Oliveira Monteschio J, Sary C, Ramos TR, del Mar Campo M,

Prado N. 2018. Consumer profile and acceptability of cooked beef steaks

with edible and active coating containing oregano and rosemary essential oils.

Meat Science. 143, 153–158.

Wan VCH, Lee CM, Lee

SY. 2007. Understanding consumer attitudes on edible films and coatings:

Focus group findings. Journal of Sensory Studies 22, 353–366.

%20in%20full.JPG)

0 comments:

Post a Comment