Mark Joseph R. Rafael,

and Ravelina R. Velasco, from the different institute of the philippines, wrote a research article about, Tilapia By-products: Characterizing

Fish Protein Hydrolysate, entitled, "Characterization of Fish protein

Hydrolysate from Tilapia by-products using acid and enzymatic hydrolysis".This

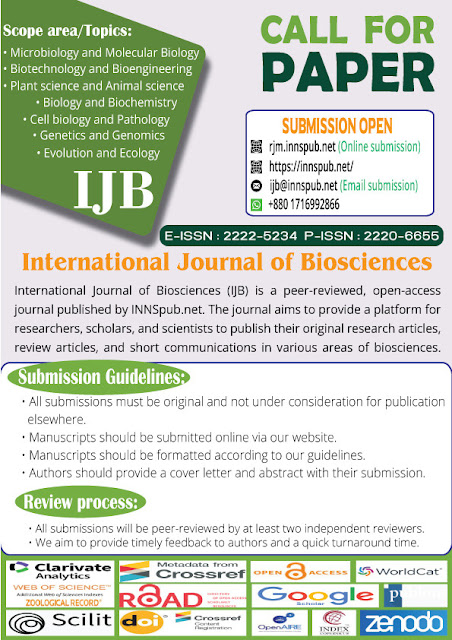

research paper published by the International Journal of Biosciences | IJB. an

open access scholarly research journal on Biosciences, under the affiliation of

the International Network For Natural Sciences | INNSpub.an open access

multidisciplinary research journal publisher.

Abstract

Waste management has been a significant problem in the fish processing industry due to environmental and public health impacts. Food products can be developed from the by-products of the aquaculture industry. This study extracted and characterized fish protein hydrolysate (FPH) from tilapia by-products (viscera). It was produced by enzymatic and acid hydrolysis. The degree of hydrolysis (DH), protein pattern, solubility, emulsifying, and foaming properties of the FPH were determined. The yield of the fish protein hydrolysate increased with increasing concentration for acid hydrolysis. Decreasing total protein was observed with the use of increasing HCl concentration. The DH ranged from 12.79-13.95%. The molecular weight distribution of fish protein hydrolysate using acid and enzymatic hydrolysis was analyzed by SDS-PAGE. Limited hydrolysis formed larger peptides which led to improved emulsification and foaming properties of the fish protein hydrolysate. Tilapia intestine crude enzyme hydrolysis produced FPH with higher solubility in water than using acid solutions. The optimum concentration for acid hydrolysis to produce FPH with high emulsifying activity index was found to be 4M acid solution. The Foaming stability for both the acid and enzymatic hydrolysis were low ranging from 9.17% 10.83%. Based on their characteristics and quality, fish protein hydrolysate extracted using acid and enzymatic hydrolysis were within the criteria that can be used as a value-added product in nutraceutical supplements such as sources of small peptides and amino acids in dietetic foods. The improved solubility, emulsifying and foaming capacities of tilapia protein hydrolysate warrant its application in formulated food systems.

Read more : Halophilic Mycoflora:Exploring Coastal Diversity in India | InformativeBD

Introduction

Tilapia are prepared by bleeding, gutting, beheading, filleting, skinning, and trimming before being bought by consumers. The potential use of fish by-products should be considered. Increasing focus on the utilization of fisheries by-products in product development and value addition can be explained through waste management efforts and characterization of the raw materials as a potential food protein source and functional foods. Several food products could be obtained from the wastes of the aquaculture by-products industry.

Fish protein hydrolysates are products of hydrolysis reaction by breaking the peptide bonds in proteins resulting in shorter peptides or amino acids which are easier for animals to absorb. Extraction of proteins from by-products and conversion to high value products, such as bioactive peptides is a very promising alternative. Bioactive peptide production from fish by-products has received growing attention due to their physiological activities as antioxidant and antihypertensive suitable for healthcare and nutraceutical applications (He et al., 2013; Je et al., 2005; Jung et al., 2006).

The considerable volume of tilapia produced in the country,

aside from the significant requirement for processing before final sale

generates a large amount of solid waste or residues and by-products, which

account for up to 70% of the total fish weight. These so-called wastes composed

of the head, carcass, bones, skin, fins and viscera of tilapia are

traditionally considered of low economic value and are disposed in land-based

waste disposal system or at sea. Moreover, a large amount of fish is also being

discarded each year due to fish kill and disease outbreaks. If not properly

discarded or used, they can be an important environmental contamination source

since the release of these organic wastes might significantly change the

community structure and biodiversity of the benthic assemblages(Caruso, 2015).

It is estimated that 32 million tons of waste are produced from the total fish

capture and are not used as food (Kristinsson & Rasco, 2000). One of the

important waste reduction strategies for the industry is the recovery of marketable

by‐products from fish wastes (Arvanitoyannis & Kassaveti, 2008). The study

was conducted to produce and characterize fish protein hydrolysate from tilapia

by-products.

Reference

Abdul-Hamid A, Bakar J,

Bee GH. 2002. Nutritional quality of spray dried protein hydrolysate from

Black Tilapia (Oreochromis mossambicus). Food Chemistry 78(1), 69-74.

https://doi.org/ 10.1016/S0308-8146(01)00380-6

Arvanitoyannis IS,

Kassaveti A. 2008. Fish industry waste: Treatments, environmental impacts,

current and potential uses. International Journal of Food Science &

Technology 43(4), 726-745.

https://doi.org/10.1111/j.1365-2621.2006.01513.x

Bhaskar N, Mahendrakar

NS. 2008. Protein hydrolysate from visceral waste proteins of Catla (Catla

catla): Optimization of hydrolysis conditions for a commercial neutral

protease. Bioresource Technology 99(10), 4105-4111. https://doi.org

/10.1016 /j.biortech.2007.09.006

Caruso G. 2015.

Fishery Wastes and By-products: A Resource to Be Valorised. Journal of

Fisheries Sciences 5.

Cheison SC, Zhang SB,

Wang Z, Xu SY. 2009. Comparison of a modified spectrophotometric and the

pH-stat methods for determination of the degree of hydrolysis of whey proteins

hydrolysed in a tangential-flow filter membrane reactor. Food Research

International 42(1), 91-97. https://doi.org/

10.1016/j.foodres.2008.09.003

El-Beltagy AE, El-Adawy

TA, Rahma EH, El-Bedawey AA. 2004. Purification and characterization of an

acidic protease from the viscera of bolti fish (Tilapia nilotica). Food

Chemistry 86(1), 33-39. https://doi.org/10.1016 /j.foodchem. 2003.08.

He S, Franco C, Zhang

W. 2013. Functions, applications and production of protein hydrolysates

from fish processing co-products (FPCP). Food Research International 50(1), 289-297.

https:// doi.org /10.1016/j.foodres.2012.10.031

Hoyle NT, Merritt

JH. 1994. Quality of Fish Protein Hydrolysates from Herring (Clupea

harengus). Journal of Food Science 59(1), 76-79.

https://doi.org/10.1111/j.1365-2621.1994.tb06901.x

Je J, Park P, Kim

S. 2005. Antioxidant activity of a peptide isolated from Alaska pollack (Theragra

chalcogramma) frame protein hydrolysate. Food Research International (Ottawa,

Ont.), 38(1), 45-50. AGRICOLA. https://doi.org/10.1016

/j.foodres.2004.

Jung WK, Mendis E, Je

JY, Park PJ, Son BW, Kim HC, Choi YK, Kim SK. 2006. Angiotensin

I-converting enzyme inhibitory peptide from yellowfin sole (Limanda aspera)

frame protein and its antihypertensive effect in spontaneously hypertensive

rats. Food Chemistry 94(1), 26-32. https://doi.org

/10.1016/j.foodchem.2004.09.048

Kim SK, Park PJ, Byun

HG, Je JY, Moon SH, Kim SH. 2003. Recovery of Fish Bone from Hoki (Johnius

belengeri) Frame using A Proteolytic Enzyme Isolated from Mackerel Intestine.

Journal of Food Biochemistry 27(3), 255-266. https://doi.org/ 10.1111

/j.1745-4514.2003.tb00280.x

Klompong V, Benjakul S,

Kantachote D, Shahidi F. 2007. Antioxidative activity and functional

properties of protein hydrolysate of yellow stripe trevally (Selaroides

leptolepis) as influenced by the degree of hydrolysis and enzyme type. Food

Chemistry 102(4), 1317-1327.

Kristinsson HG, Rasco

BA. 2000. Fish Protein Hydrolysates: Production, Biochemical, and

Functional Properties. Critical Reviews in Food Science and Nutrition 40(1), 43-81.

https://doi.org /10.1080/10408690091189266

Navarrete del Toro MA,

García-Carreño FL. 2003. Evaluation of the Progress of Protein Hydrolysis.

Current Protocols in Food Analytical Chemistry 10(1), B2.2.1-B2.2.14.

https://doi.org /10.1002 /0471142913.fab0202s10

Ovissipour M, Abedian

A, Motamedzadegan A, Rasco B, Safari R, Shahiri H. 2009. The effect of

enzymatic hydrolysis time and temperature on the properties of protein

hydrolysates from Persian sturgeon (Acipenser persicus) viscera. Food

Chemistry 115(1), 238-242. https://doi.org/10.1016

/j.foodchem.2008.12.013

Shahidi F. 2007.

Maximising the Value of Marine By-products. Cambridge: Woodhead. http://www.

crcnetbase.com /isbn/9781439824542

Silva JFX, Ribeiro K,

Silva JF, Cahú TB, Bezerra RS. 2014. Utilization of tilapia processing

waste for the production of fish protein hydrolysate. Animal Feed Science and

Technology 196, 96-106.

https://doi.org/10.1016/j.anifeedsci.2014.06.010

Šližyte R, Daukšas E,

Falch E, Storrø I, Rustad T. 2005. Yield and composition of different

fractions obtained after enzymatic hydrolysis of cod (Gadus morhua)

by-products. Process Biochemistry 40(3-4), 1415-1424.

https://doi.org/10.1016 /j.procbio.2004.

Stoyanov J, Hobman J,

Brown N. 2001. CueR (YbbI) of Escherichia coli is a MerR family regulator

controlling expression of the copper exporter CopA. Molecular Microbiology.

https://onlinelibrary.

Wisuthiphaet N,

Kongruang S, Chamcheun C. 2015. Production of Fish Protein Hydrolysates by

Acid and Enzymatic Hydrolysis. Journal of Medical and Bioengineering, 4(6), 466-470.

https://doi.org /10.12720/jomb.4.6.466-470

Yang H, Xue Y, Liu J,

Song S, Zhang L, Song Q, Tian L, He X, He S, Zhu H. 2019. Hydrolysis

Process Optimization and Functional Characterization of Yak Skin Gelatin

Hydrolysates Journal of Chemistry; Hindawi.

https://doi.org/10.1155/2019/9105605

%20in%20full.JPG)

0 comments:

Post a Comment